A reference link has been placed below the calculator for further reading.

Heat sink calculator free.

Click below to learn more.

Heat transfer design and engineering.

Devices are encapsulated in packages which have different levels of thermal resistance.

Heat sink calculator is a tool for designing analysing and optimizing heat sink performance contact us today for custom heatsink solutions.

Power components have a maximum junction temperature which must not be exceeded to prevent damage to the device.

How does the heat sink calculator work.

This calculator uses the calculation methodology explained in the blog posts how to design a flat plate heat sink and performance of a led flat plate heat sink in multiple orientations.

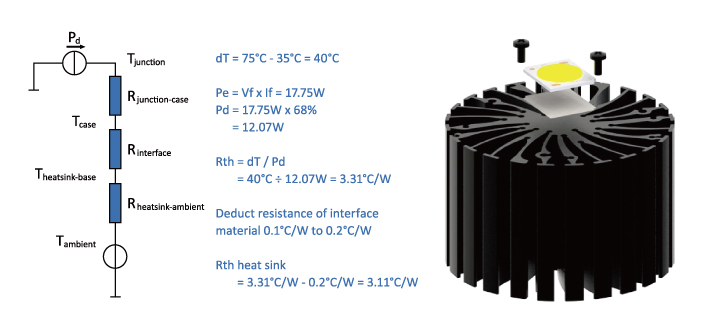

Heat sink thermal resistance calculator use this online calculator to determine the heat sink thermal resistance required to maintain a specified component junction temperature.

Calculate the thermal resistance and pressure drop of a plate fin heat sink and study how individual parameters affect the heat sink performance.

The width of the heat sink is then calculated based on the number of fins required to dissipate the heat from the heat sink.

Fins are used to increase heat transfer area and provide a cooling effect.

The heat sink size calculator is based on a well established equation for estimating heat sink volume during the early stages of heat sink design.

The maximum ambient temperature the device s junction to package thermal resistance the thermal resistance of the heat sink and the power applied.

In addition the calculator automatically determines the optimal dimensions of your heat sink to achieve the lowest heat source temperature.

Heat sink convection with fins calculator.

Use this free online calculator to estimate the performance of a flat plate used as heat sink for leds mosfets diodes or other electronic or electrical devices.

Heat sink temperature calculator.

The heat sink size calculator first calculates the optimum spacing between the fins to achieve maximum convection cooling.

In our experience it generally estimates the overall heat sink volume within 15 of a final design.

Multiple heat sources attached to the heat sink can be evaluated.

When designing power electronics the heat dissipation of the device coupled with any heat sinks as well as.

This tool is designed to calculate junction temperature of an electronic device typically power devices given four parameters.

The heat source is assumed to cover the entire base of the heat sink.